TECHNICAL SUPPORT

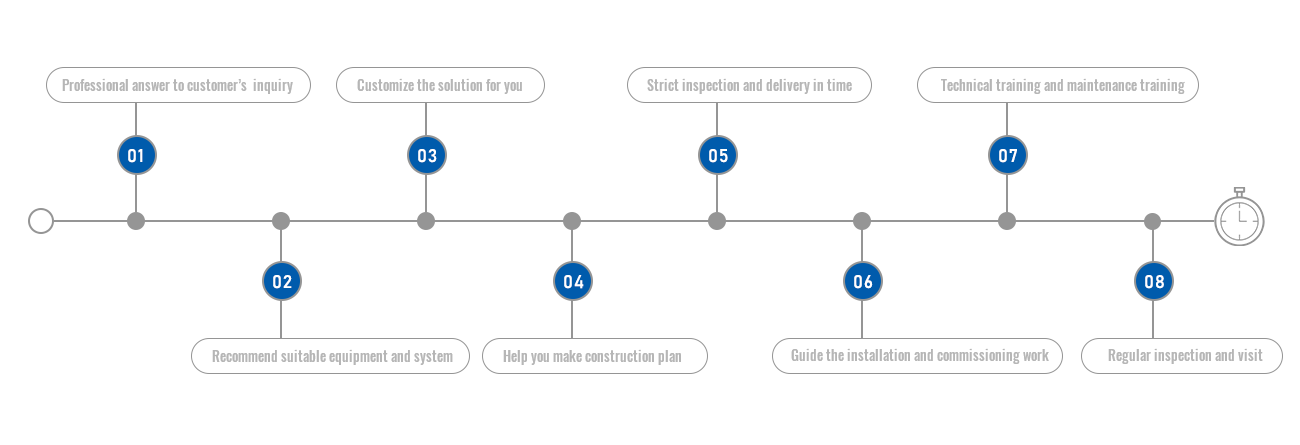

From the early equipment type selection, solution design,particle design,particle size control,particle shape,solution planning, to the mid-term equipment capacity optimization, and then to the later after-sales service, our project manager tracks the whole process for you to avoid risks and improve the value of the project.

Jet mill / impact mill/classifying mill/pin mill/hammer mill/wood fiber mill/trubo mill/drying deagglomeration mill/roller mill/vibration mill/air classifier/cutting mill/screen mill/drum mill/grinding mill Mechanical/grinding equipment/coating surface modification/micro mill/nano mill/ultrafine mill/Superfine mill

01/150+ engineers provide service

ALPA specializes in ultra-fine and ultra-pure grinding and air classifying , powder shape control and selective grinding, powder surface modifying&coating, and systematic integration of powder project equipment, we provide a complete set of design solutions and customize economic benefit analysis report to achieve sustainable development of business based on our 18 years accumulated market operation experience for the worldwide customers in more than 100 countries and regions.

03/Five quality assurances, trouble-free quality assurance service

Self built multi-functional Center Station

The company spent a huge sum of money to build a multi-functional center station integrating technical services, information feedback, spare parts supply and technical training together in headquater to provide professional service support for customers.

Technical specialist team with systematic knowledge and skills

ALPA has enough technical experts and service engineers to provide professional service to you with their many years’ skills and experience.

Quick Part Supply

The marketing service center promises quick supply of the accessories. The price of spare parts is tha same for our worldwide customers. ALPA shall bear the cost of the spare parts for repair and replacement due to equipment quality within three assurance period.

Exclusive equipment inspection service

After maintenance of equipment is finished, we provide customers with our professional exclusive equipment inspection services to ensure potential dangers can be found and eliminated in time and ensure the equipment can run safely and smoothly.

Multi- level maintenance quality control

After equipment repair is finished, it must pass our multi-level maintenance quality inspection procedures including self-inspection by maintenance technicians, re-inspection by team leaders, final inspection by workshop quality inspectors and final inspection by engineers before it is turned over to the user.