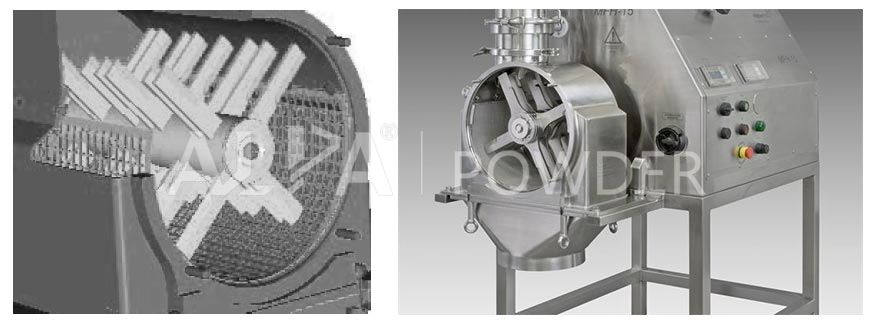

CUM-F Hammer Mill

Widely used in chemical, inorganic salt, medicine, food, pigments, dyes, pesticides, battery materials, minerals, refractory materials and other industries.

- Available D50:10~850μm.

- Sieve hole size 0.2mm-3mm.

- Compact structure and small occupation. easy to disassemble and clean

- Lower installation power, wide application, high cost-performance.

- Different installation combinations, applicable to different process requirements

- Grinding is in closed system, low dust and noise, clean and environmentally friendly production process.

- PLC control system, easy operation.

- The motor can be connected with a belt to increase the speed and break through the problem of high-speed motors without the well-known motor brand.

- Optional explosion-proof design, meet the ultra-fine grinding processing requirements of flammable and explosive oxide materials

- High-temperature, low-temperature, normal-temperature, airtight cycle, Inert gas cycle designs are available, for different grinding requirements of different materials.

CUM-F Hammer Mill

Working Principle

The material is evenly fed into the grinding chamber by the feeding system, strongly impacted by the high-speed rotating disc. At the same time, it is subjected to various comprehensive forces such as friction, shearing and collision between the static disc and the ring gear to grind material. The moving disc and static disc can be combined in different structural forms according to nature of material to meet the grinding requirements of different materials.

CUM-F Hammer Mill

Technical Parameters

| Parameters/specifications | 160 | 250 | 360 | 500 | 630 | 800 | |

|---|---|---|---|---|---|---|---|

| Turbo Type F | Grinding Disc(mm) | 150 | 250 | 350 | 500 | 600 | 720 |

| Max. Rotation Speed(r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 | |

| Power(kw) | 3~4 | 5.5~7.5 | 11~15 | 18.5~30 | 30~45 | 37~75 | |

| Product Size(mesh) | 20~325 | ||||||

| Production Capacity(Kg/h) | 5~50 | 15~200 | 25~500 | 30~1200 | 50~1800 | 60~2000 | |

| Pin Type P | Grinding Disc(mm) | 160 | 260 | 360 | 520 | 630 | 730 |

| Max. Rotation Speed(r/min) | 12000 | 7500 | 5550 | 3850 | 3200 | 2800 | |

| Power(kw) | 4 | 7.5 | 15~22 | 37 | 45~55 | 55~75 | |

| Product Size(mesh) | 20~325 | ||||||

| Production Capacity(Kg/h) | 20~200 | 35~1000 | 50~2000 | 75~3000 | 100~5000 | 200~10000 | |

Note: The production capacity is closely related to the particle size, specific gravity, hardness, moisture and other indicators of the raw materials. The above is only for selection reference.

CUM-F Hammer Mill

Album

CUM-F Hammer Mill

Related Engineering Cases

“I don’t know how to choose the best for me.”

IT DOESN’T MATTER

LET US HELP YOU!

The raw material and the particle size, output, and application industry of the finished product determine the choice of equipment and process. As an expert, you will not be unfamiliar with this.If you have any questions, don’t worry, please leave us a message, or “Live Chat” in the lower corner of this page, or contact us via our phone or email.

ANY QUESTIONS OR DEMANDS

PLEASE CONTACT US RIGHT NOW!

Learn More & Get Quotation

Please tell us your needs.

Our engineer will send you solutions and quotes for free.

Or email