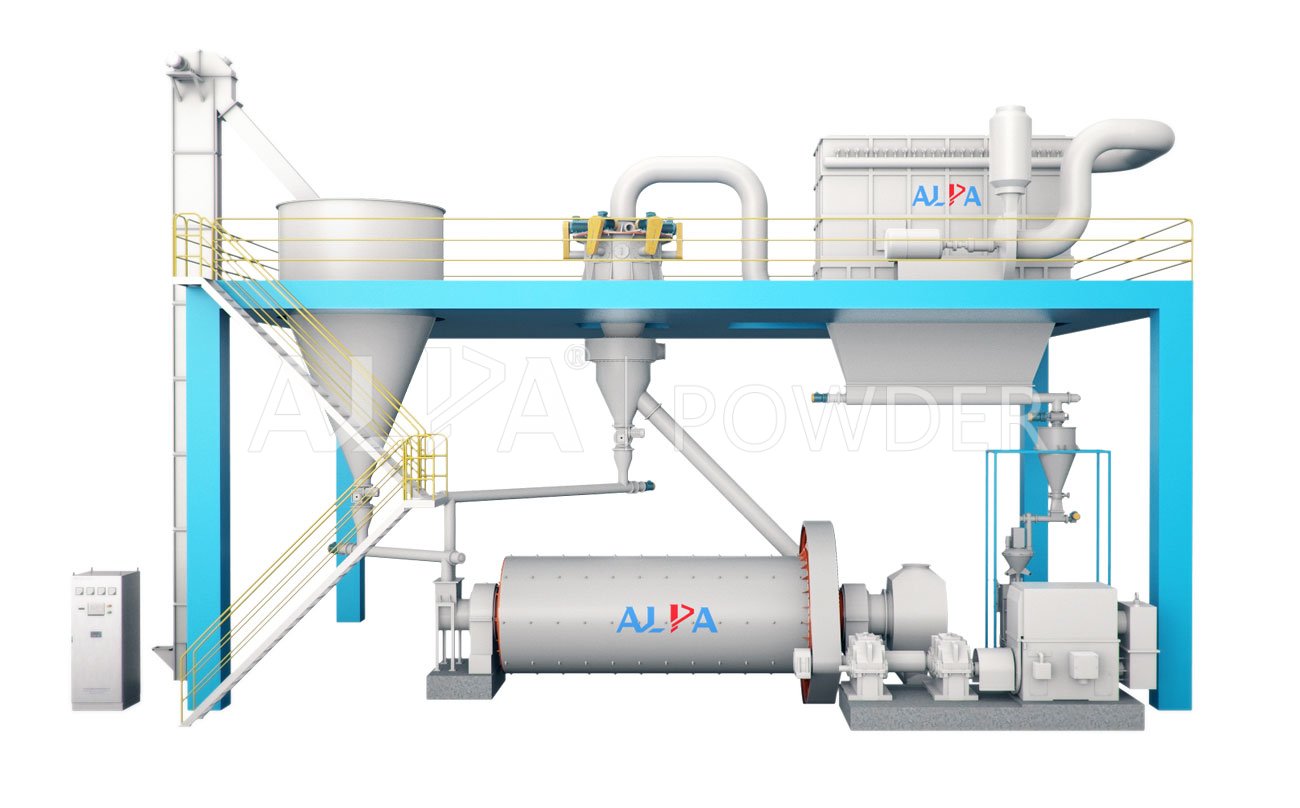

Classifying and Ball Mill Production Line

The world’s leading process line / mature technology / green / low energy consumption

Classifying / classifier / classification and

Ball Mill Production Line structure

Calcium carbonate (calcite, marble, lime stone, chalk), quartz, zircon, paillite, barite, kaoline, dolomite, magnesite, alumina, super fine cement, slag, steel slag.

Unique advantages

Large-scale, intelligent, energy-saving, low-carbon, and environmentally friendly are the missions and responsibilities that the times have given us.

Reasonable process design, low energy consumption per unit, large output

PLC control, easy to operate

Safe and stable operation and low maintenance cost

Flexible choice of grinding media and liners

Low contamination of materials with high purity

The product produced has a concentrated particle size distribution and stable product quality

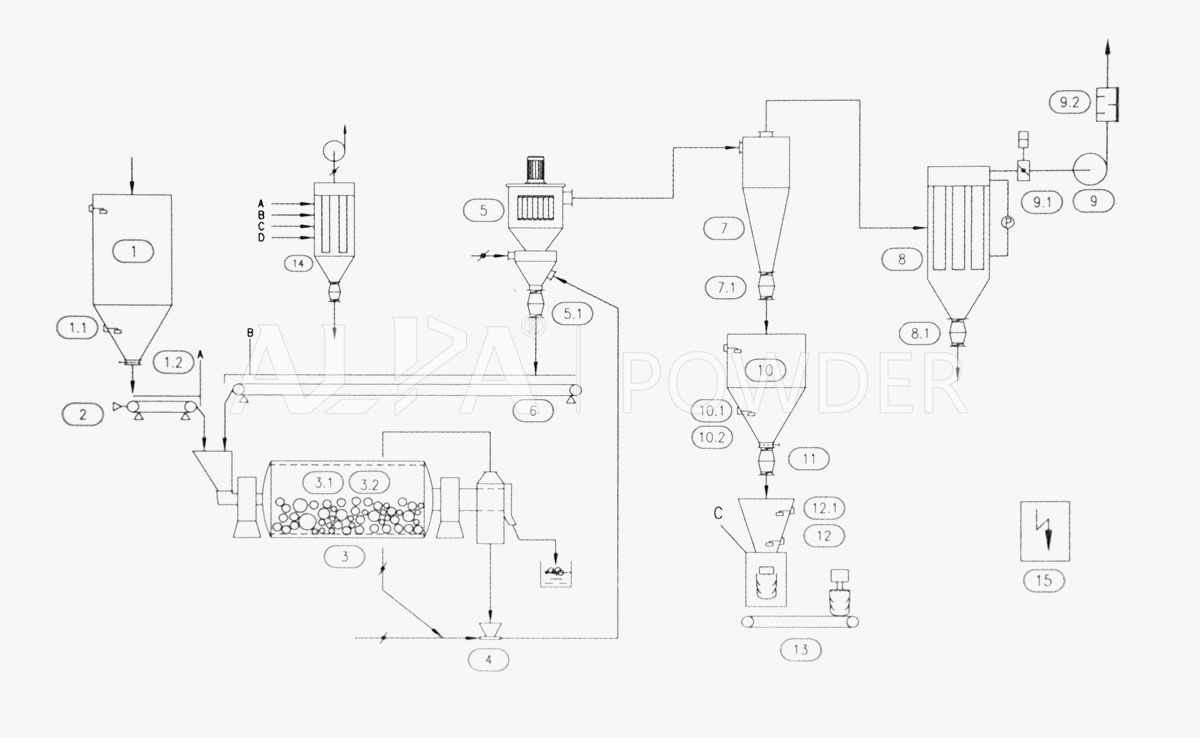

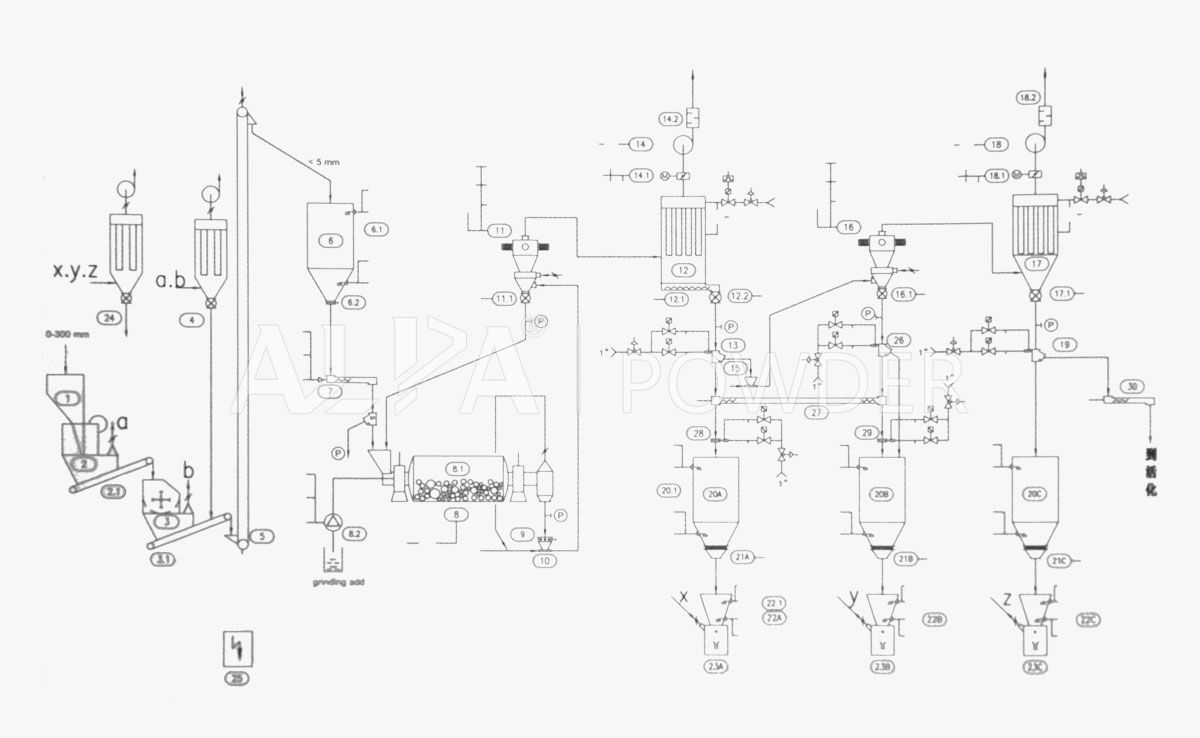

Process

Process characteristics

Source of Technology

Germany technology, international standard non-metallic minerals production line.

Technical Process

The process mainly includes crushing(generally use two stages of crushing), grinding, classifying, package, magnetic separation, transportation, lifting etc. In conjunction with several classifiers in parallel or series, several different products can be obtained at the same time.

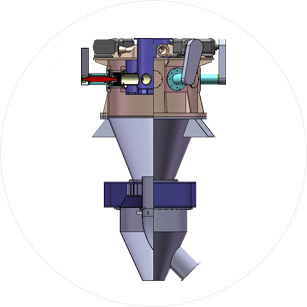

Ball Mill

Special design to ball mill which will be selected on the basis of material’s hardness, grindability index, final particle size and capacity. The shape of the lining and the ball (segment) are tailored according to years of engineering practice experience to maximize the grinding efficiency of the ball mill and reduce the energy consumption.

Classifier

Different models of Classifier could be selected depending on different fineness of products. FW series Classifier are suitable for classifying of D97:3~20μm products, FL series for classifying of D97: 8~45μm products. Wide range of adjustment is available with each Classifier and the application is extensive in market.

Flexible control of product particle size

The production line are designed and optimized to match with several classifier in series, the particle size can be controlled, and several products can be obtained at once, low energy consumption, free from over-crushing.

Low noise and emission

Environment protection design to the vibration damper, component soft connection and filter bag result in lowering noise and dust.

Automatic Control

The electric control system employs programmed control for the entire process from feeding, classifying and grinding to packing.

Personalized customization

According to the customer’s investment scale, we can design different plant structures and equipment layout schemes to provide the most cost-effective configuration system. For example, the equipment layout with an annual output of less than 20,000 tons is mostly arranged in a single-storey factory layout, and the conveying system adopts spiral conveying. The equipment layout of the scale of more than 20,000 tons adopts the multi-layer factory three-dimensional arrangement, the conveying system adopts pneumatic conveying, and the packaging adopts automatic packaging and equipped with palletizing system.

Provide value-added services

Add-on services to customer such as mineral processing, modification, granulation and equipment upgrading.

Process example

Various types of powdered raw materials that are crushed, beneficiated, calcined or melted

Hoister

Stock Bin

Classifier

Ball mill

Electromagnetic vibrating feeder

Cyclone collector

Bag dust collector

Finished product

Major equipment

Ball mill

- The design is different from traditional cement mills and mining and metallurgical mills, and meets the requirements of German superfine filler grade mineral processing.

- Optimize the aspect ratio to prevent excessive grinding and achieve optimum grinding results.

- Optimize the opening ratio and opening design of the jaws, and increase the grinding fineness with a smaller grinding media.

- The slab-type grinding tail discharges, the discharging is smooth, there is no grinding phenomenon, and the cylinder does not need to be cooled.

- Grinding media according to product requirements, reasonable ratio, high filling rate, high efficiency.

- Grinding aids when grinding ultrafine powders to improve grinding efficiency.

- Optimize the matching of drive and grinding energy to maximize energy savings.

- And the classifier forms a closed system, negative pressure conveying, no dust.

- Optimize the shape and material of the lining and grinding media, according to German standards, reduce the damage rate and improve the grinding efficiency.

- Hard minerals can be designed with no iron pollution, and the lining and grinding bodies are made of alumina ceramic, quartz, SILEX or special materials.

Classifier

Different models of Classifier could be selected depending on different fineness of products. FW series Classifier are suitable for classifying of D97:3~20μm products, FL series for classifying of D97: 8~45μm products. Wide range of adjustment is available with each Classifier and the application is extensive in market.

Quantitative system

- Ball mill feedstock adopts a precise quantitative system, which can stabilize the feed even if the density of the material changes.

- Classifier feedstock adopts a precise quantitative system and interlocks with the discharge of the ball mill to ensure the stability of the system operation and product granularity;

- High-precision metering pump, according to fineness requirements of product, spray the grinding aid into the mill with accurate time and dosage;

- The damper valve has an airflow measurement system that allows accurate control of the flow volume and rate of classifying.

Control systems

- Both the material silo and product silo have leveler, which can realize automatic control of the entire production line;

- Using PLC control, the light flow chart shows the running status, which is clear and easy to operate.

Environmental protection and noise control

- Adopt membrane filter bag, dust emission is less than 20mg/m3;

- Adopt efficient muffler, exhaust noise <80dB(A);

- All heavy-duty moving parts have shock absorbers;

- There is no waste water discharge, only the cooling water of the ball mill bearing and can be recycled.

Main equipment specifications and parameters of ball mill classifying production line (taking calcium carbonate as an example)

| Model | IBM1830 | IBM2200 | IBM2400 | IBM2600 | IBM2800 | IBM3000 | |

|---|---|---|---|---|---|---|---|

| Power (KW) | 220 | 320 | 450 | 630 | 710 | 800 | |

| Classifier | Model | 1 machine FW630/4 | 1 machine FW630/6 | 2 machine FW630/4 | 1 machine FW630/6 | 1 machine FW800/4+1 machine FW800/6 | 2 machine FW800/6 |

| Power(KW) | 192 | 290 | 384 | 580 | 670 | 764 | |

| Auxiliary equipment power(KW) | Crush System | 37 | 55 | 65 | 90 | 90 | 110 |

| Conveyor packaging | 11 | 22 | 22 | 30 | 37 | 37 | |

| Air compressor | 18.5 | 30 | 45 | 55 | 75 | 90 | |

| Particle size and productivity(T/H) | D97 15um | 2.7 | 4.0 | 5.4 | 8.0 | 9.4 | 11 |

| D97 10um | 2.0 | 3.0 | 4.0 | 6.0 | 7.0 | 8.0 | |

| D97 5um | 0.9 | 1.3 | 1.8 | 2.7 | 3.0 | 3.6 | |

Main equipment specifications and parameters of ball mill classifying production line (taking quartz as an example)

| Model | IBM1570 | IBM1830 | IBM2200 | IBM2400 | IBM2600 | |

|---|---|---|---|---|---|---|

| Power (KW) | 75 | 160 | 245 | 320 | 560 | |

| Classifier | Model | 1 machine FL360 | 1 machine FL450 | 1 machine ITC3 | 1 machine ITC4 | 1 machine ITC5 |

| Power (KW) | 48 | 73.5 | 105 | 120 | 197 | |

| Auxiliary equipment power(KW) | Conveyor packaging | 5 | 11 | 11 | 11 | 22 |

| Air compressor | 7.5 | 11 | 15 | 15 | 22 | |

| Particle size and productivity(T/H) | D90-92 45um | 1.0 | 2.0 | 3.0 | 4.5 | 6.7 |

| D90-92 15um | 0.5 | 1.0 | 1.6 | 2.7 | 3.4 | |

| D90-92 10um | 0.35 | 0.75 | 1.0 | 1.5 | ||

Capacity matching

ALPA’s ball mill classifying production line with reasonable production capacity, large output, stable operation and stable product quality.

Influencing factors of Ball mill output

- Feeding particle size and distribution;

- Scientific calculation of the length to diameter ratio of the mill;

- Speed of the ball mill and motor power of the mill motor;

- Shape and material of ball mill medium;

- Loading quantity of the mill medium.

Influencing factors of Classifier output

- Powder concentration;

- Turbine classifier rotate speed;

- Air volume and Air pressure;

- Classifying efficiency;

- Particle size distribution;

- Product fineness.

The relationship between Ball Mill and Classifier

- Ball Mill Output = raw material feed amount + coarse material return after classifying

- Classifier Output = classifier throughput – classified coarse material

- Classifier throughput = Ball Mill output

ALPA’s ball mill classifying production line, ball mill and classifier work well together, can complement each other, high efficiency, large output, stable operation and stable product quality.

Related engineering case

Service and Support

Quality Management

ALPA’s quality assurance goal is to pursue the zero defects of all manufactured ultrafine powder equipment, actively implement Six Sigma quality management, and continuously improve process control management capabilities through advanced statistical analysis to ensure products and services are satisfied for customers.

“I don’t know how to choose the best for me.”

IT DOESN’T MATTER

LET US HELP YOU!

The raw material and the particle size, output, and application industry of the finished product determine the choice of equipment and process. As an expert, you will not be unfamiliar with this.If you have any questions, don’t worry, please leave us a message, or “Live Chat” in the lower corner of this page, or contact us via our phone or email.

ANY QUESTIONS OR DEMANDS

PLEASE CONTACT US RIGHT NOW!

Learn More & Get Quotation

Please tell us your needs.

Our engineer will send you solutions and quotes for free.

Or email